How to avoid the 5 biggest blunders with glass block showers

Updated April 19, 2020

The process of building a glass block shower seems mysterious to many. How is this wall going to be built? Who is going to do it? How do we plan the glass block shower so it will fit onto the shower pan? Is there a way to do this project so it doesn’t cost us an ‘arm and a leg?’ In short how do we make this project happen so it doesn’t get screwed up?

As a result of lack of planning over the years I have been called (unfortunately after the fact) on many glass block showers which either look like a 10 year old (or some very inexperienced dude) built them or have failed as a result of using the wrong materials or improperly designed shower base. I really don’t want to see these blunders happen to you!

In the article below we’ll take a quick journey to explore the 5 biggest blunders I’ve seen in glass block shower walls – but way more important than that I’ll give you the solutions to avoid these costly mistakes. And with a recent update to this article we’ll look a 6th blunder at the end you won’t want to miss so you’ll keep your budget in tact. Let’s dig in!

Blunder #1 – “The Field of Dreams Blunder” – Build it (the shower base) and then the glass block wall will come

Being a “glass half full” kind of guy I have to tell you I love the movie Field of Dreams and the hope it inspires. Unfortunately in construction if you build something (a glass block shower wall in this case) without a complete plan on how all the components (the base plus the walls) are going to work together you have the recipe for a disaster!

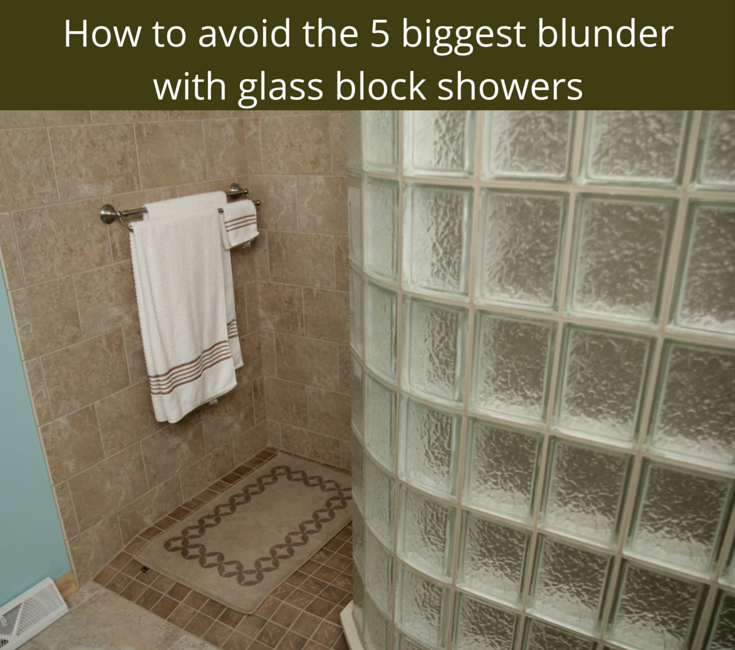

In the case of a glass block shower wall (and especially one with a curved design) the walls need to be built on top of the shower pan’s curb – and since you can’t cut glass blocks – if the pan is not designed with the wall in mind you’re going to have big problems making the glass blocks fit. If you look at a glass block curved wall with huge grout joints you’ll see this “Field of Dreams” blunder in full bloom.

How to avoid blunder #1 – a shower pan and a glass block wall which work together

With the glass block shower kit systems available today (even for custom glass block showers) it’s simple to avoid blunder #1. You can get a shower pan with a curb which has been manufactured with the specific design of the wall in mind. In the shower below a ‘ready for tile’ shower pan was built with the shape of both the straight and curved prefabricated glass block shower walls.

This will take all the guesswork out of making sure the wall and the base will match up (so you won’t end up with huge joints which will be prone to crack and don’t look very nice!).

In the example below a solid surface shower pan was made to fit this glass block wall. This is a double-bonus – a low maintenance base and a premade (simple to install) glass block wall.

Blunder #2 – “The Rust Belt Wall” – Rust in the grout joints

While I am proud to say I grew up in Cleveland which was previously thought of as a rust belt city – my tolerance (or anyone else’s for that matter) to see any rust between the joints in a glass block shower wall is ZERO! With that being said I have gone out on appointments where rust has appeared between the glass block courses. The owner will ask, “how can you fix this?” The solution is tear it down – ouch! The reason rust has appeared in the first place is reinforcing wire was used between the blocks (for stability) and over time water made contact with this metal wire by penetrating the grout joint and caused rust to happen. Fortunately, there’s a simple (if you do it while building the wall in the first place) fix to this blunder.

How to avoid blunder #2 – rust in the glass block joints

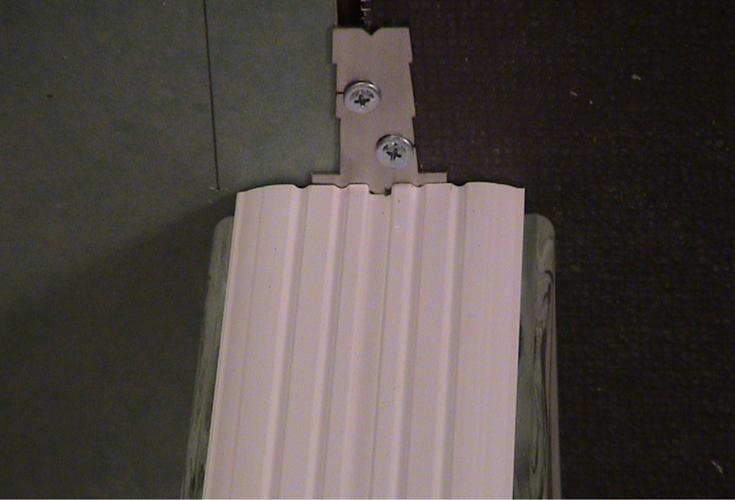

If you use a vinyl Protect All Installation stacking system between the glass block courses it will not only provide even better structural support for the wall than with wire – but the material will never rust. Say goodbye to blunder #2!

Blunder #3 – A glass block wall with no support system

Whether on a personal level – or in building a glass block shower wall – a support system is critical. If a glass block wall is not anchored into one side wall you can have a problem of the wall moving if the home settles. This problem fortunately has a simple solution.

How to avoid blunder #3 – a wall with an effective anchoring system

To ensure a stable wall structure which will not move include an anchor every 16 to 24″ as the wall goes up. In the Protect All vinyl stacking system the anchors will be used every 2 to 3 courses (this is every 16 to 24″) and will be fastened to the side wall.

It is recommended to have wood blocking in the side wall for the best structural support.

Blunder #4 – The Goldilocks dilemma – This walk in shower opening is too big, now this one is too small

The story of Goldilocks takes me WAAAY back! You may remember after Goldilocks had eaten the three bears porridge she was tired and looked for a chair to rest in (one was too small, one was too large the last one was just the right size). Determining the size of a glass block shower opening is same process – it’s about finding just the right size (making sure the opening is neither too big or too small for all the people who will use it both now and in the future). In reality designing a shower opening is all about trading inches to get it just right for your needs.

How to avoid blunder #4 – getting a walk in shower opening just the right size

Since glass block showers can make a cost effective curved wall they are popular for walk in showers – as a matter of fact – I would estimate 75% of the glass block showers we sell are walk ins.

To take the guesswork out of designing this opening I would recommend reading 5 Proven Questions to Get the Size of Your Shower Opening Right.

Blunder #5 – The dude installing this glass block shower wall seems clueless!

Ouch – there is nothing quite as scary as having spent good money for a custom glass block shower and the actual guy doing the work appears clueless (and this problem is getting bigger as more young people stop pursuing the construction trades as a career). Since glass blocks are a niche specialty project it may not be possible to find an experienced installer in all areas of the country. Once the “not-so experienced” installer (who might have been hired by your general contractor) shows up on your doorstep it may be challenging to fix his poor work after the fact. There is a way to eliminate the worries about who is installing your project.

How to avoid blunder #5 – the incompetent glass block installer

The reason most of us fail at something is we don’t have a proven system or process which makes the task easier. Taking the challenge out of a custom glass block shower wall and base installation is as simple as buying a glass block shower kit. The kit will come with the glass block walls premade (even if they have a curved design) and a shower pan (there are ready for tile, solid surface or acrylic options) so it simplifies the installation process and can be done by a first time contractor or DIY homeowner.

Bonus Blunder #6 – You buy the blocks first, and you’re gonna’ figure out the costs later

As the old saying goes, if you fail to plan you plan to fail. Since glass blocks can’t be cut, and in many cases will be installed by a contractor (or DIY’er) doing it for the first time – it’s important to have a plan about the size of the wall, it’s shape and the type of shower base you’ll use. Otherwise you may buy materials you don’t need and run up costs you didn’t need to have. So, the question is how can you avoid this problem?

How to avoid blunder #6 – the glass block shower installation job you have NO IDEA WHAT IT’S GOING TO COST

If you go into a project with an ‘open checkbook,’ there is one thing you know for certain – you’ll pay waaaaaay too much doggone money for it. Don’t be a victim of a lack of project planning and runaway costs. Here’s what you can do to stop this problem in its tracks.

Develop a design (including the size/shape of the shower base and the wall). Talk to a glass block designer and supplier to get you a price of a glass block shower wall and the base you’ll need with it. Don’t buy what you think you’ll need and try to figure it out on the fly. Take the time to read the article below about the cost of a prefabricated glass block shower wall system. This will get your budgeting process started.

Conclusion

While this article has pointed out the biggest blunders with a custom glass block shower wall there is no need to be fearful of this project. To take the worry out talk to a supplier with glass block design, supply and installation expertise (and yes – my company has been doing glass block shower designs from what seems like the time Moses was a boy – OK, it’s ONLY been since 1977). Simplify your life and do it right the first time.

For more information call Innovate Building Solutions at 877-668-5888. We provide factory wholesale distribution of glass block shower bases and prefabricated shower walls.

If you’re a remodeler or builder and want practical advice on remodeling products, industry trends, marketing and sales tips to grow your business (and cut day to day hassles), start reading my newest blog – Innovate Builders Blog. It’s packed with ideas you can use now. Click here to Sign Up for the Innovate Builders Blog.

Mike Foti

Scott – our unframed glass block walls can be made in 2″ increments. So we could prefabricated a 42″ x 34″ or 42″ x 38″. Give us a call for more in depth assistance. Mike

Scott

Do you make a custom wall to fit a 42″ width x 33 to 38″ height hole. With mounting hardware and brackets

Mike Foti

Jim – we usually don’t need to use any sealant with a mortared glass block window (assuming the joints are tooled properly). When we do the installation we usually recommend using a Type S mortar and silica sand mixture (there should be about 2 parts of sand to one part of mortar). I hope this helps you – Mike

Jim DeLaPlaine

Can you recommend a penetrating sealer for glass block mortar in a window installation?