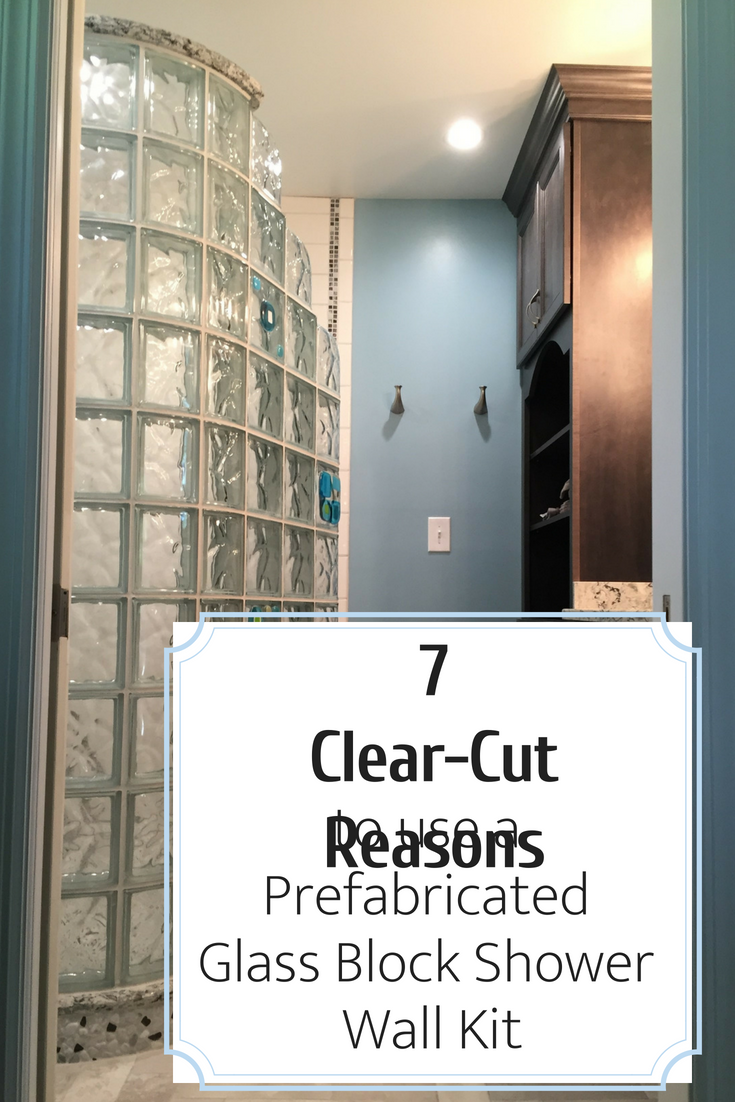

7 Clear-Cut Reasons to Use a Prefabricated Glass Block Shower Wall Kit

Updated March 23, 2019

I’m going to say it right up front.

Glass block shower walls can be a pain in the butt to install.

Here’s 3 facts I know to back up this statement:

Fact #1 – It’s not the type of job you (or your contractor) do every day – Most people doing a glass block shower wall are embarking (sounds like we’re boarding a plane), on this journey for the first time. So, you’re a newbie. Doing any home improvement for the first time (let alone a unique niche like glass blocks) can be unnerving, scary and can painfully eat up your time and pocketbook, if you’re not careful.

Fact #2 – You (or your general contractor) are desperately trying to find a needle in a haystack– If you’re lucky enough to find a mason contractor to lay up the glass blocks piece by piece you’ll likely get an old ‘grizzled veteran’ who will look like the guy below, not some hot strapping guy with no shirt like Matthew McConaughey. This old-time mason contractor will know he’s got you by the ‘you-know-what’s’ (who else are you going to get to do this job?) and will price you (and treat you) accordingly. He is “THE MAN” and will carry himself on your job as such. No “Nordstrom’s style” customer service here.

Fact #3 – If you want an out-of-the-ordinary glass block wall – look out! Perhaps you noticed a cool curved walk in shower on Pinterest. You’ve seen on Google a glass block wall with fun colors, or interesting grouping of sizes and patterns. You’re tired of one 8 x 8 x 4 glass block stacked on top of another. Unless you have a glass block specialty contractor in your home town (and most don’t have such an animal) – you’ll need someone to figure out your unique wall and how to build it.

So, if your heart is set on getting a glass block shower wall (and you also need the shower pan to go with it), the question becomes how are you going to make this happen without re-inventing the wheel? Here’s the simple answer:

Use a prefabricated glass block shower wall and base kit

In this article I’m going to give you with 7 clear-cut (yes- pun intended) reasons a glass block shower kit is a smarter choice than dealing with a old grizzled cocky mason contractor, or trying to build it block by block yourself. After reading these reasons let me know if you’re more confident to take on this job. My goal is to make you victorious in your quest for a glass block shower – with minimal hassle along the way.

Reason #1 to use a prefabricated glass block shower wall– Small is the key when it comes to grout joints

How many of you LOVE big grout joints? If you raised your hand, I’ll have the nurse over shortly to bring you your ‘special medication.”

There are cases where bigger is better. Big defensive tackles on the line of your football team are a good thing. Being big as a Sumo wrestler is also good. I’m a huge fan of big rolls of toilet paper. Big is good if you’re getting a raise or come up with a big idea.

Big is not a good if you’re talking about glass block mortar joints.

If you (or your mason) build your wall using the ‘old school’ block by block method, you’ll end up with ¼” or larger mortar joints (Note – these will be significantly larger if you’re building a curved wall). Bigger joints = more work for you and an uglier job at the end.

When you get prefabricated glass block shower walls using a Protect All system, you’ll have tight 1/8” joints (at least 50% smaller than the block by block method). In addition, you can use urethane grout so the joints don’t require resealing down the road (note – you’ll never see any contractor who installs a glass block or tile wall offering to come to your home for the next 10 years to clean these joints for you).

Reason #2 to use a prefabricated glass block shower wall– Cut the installation time and the installation expense

I bet you love having contractors in your house. They practically become members of the family! Well –sometimes you like having them around. In most cases, even the best contractors are a nuisance. They are necessary means to an end. They are something you have to ‘put up with’ to get a beautiful bathroom.

Well – wouldn’t it be special if you could find an installation method which saved time (i.e. contractors were at your home less)? Wouldn’t it be special if you decide to DIY it and the installation process is so easy you’re on the golf course quicker and will spend less in the process?

With a prefabricated wall, even a curved design can be made in easy to handle sections (usually the sections weigh between 50 to 60 pounds). They stack one on top of another like LEGO blocks. With these stacking sections you won’t need a mason (more about that later).

Reason #3 to use a prefabricated glass block shower wall– Less mess

I know my wife Rose loves this benefit. There is nothing nastier than a house blown apart by remodeling. With the old-style traditional glass block shower wall your contractor builds a ‘mud-set’ shower pan (this is a shower base made of concrete) and then the blocks are put up one by one.

The mud-set (or mortar) shower pan is cheap (that’s good), but it’s a mess to build and has a way-too-high failure rate (a shower pan which fails = a disaster!). A block wall built unit by unit takes a lot of time and has big mortar joints (another big mess).

Glass block shower kits with a stone base and premade wall dramatically cut the mess. Since the wall is premade (and only needs thin grout joints on the outer edge) you’ll have less grouting than a tradition mortar wall. In addition, if you use a cultured stone shower pan you simply set the wall on top of the base and join the vinyl spacer assembled into the wall with silicone onto the base. Simpler, easier and less mess – sounds good to me.

Reason #4 to use a prefabricated glass block shower wall– Build a fun, complex wall, even if you or your contractor are a rookie

Trying to do a wall block by block with multiple sizes can be a nightmare – even for the best glass block installation craftsman in the world. With a premade wall the funky sizes and colors are built into sections. You simply stack the panels one on top of another. The ‘puzzle pieces’ are pre-built for you.

Easy-peasy-lemon-squeezy as one of co-workers likes to say.

If you are installing a glass block wall for the first time you’ll also want to read 5 Little Known Tips to Build a Glass Block Walk in Shower for the First Time.

Reason #5 to use a prefabricated glass block shower wall– No more begging, no more groveling at the feet of a contractor

Mason contractors who work with bricks and blocks – hate glass blocks. When my Dad was alive we had a commercial union, mason contracting business. Whenever Dad got a glass block job he only would send 2 of the 40 masons he had on the payroll to do it. Why, you might ask?

Well, some guys would fly through the installation and the blocks would ‘swim’ all around (that’s what a mason calls units which move around while you’re installing them) and end up all catawampus (now, that must be the funniest sounding word ever!). Other guys would be as slow as molasses. He needed the right combination of speed and quality.

When it comes to a residential job there aren’t many masons willing to do this job. The ones you do find may be like a character I call- Pasquale Primadonna. You know Pasquale – he tries to make you feel you’re lucky to even have him on your job. He’s cocky, and in today’s marketplace, he’s busy. He’ll show up a week late and not give a hoot about your schedule.

With a prefab wall you’ll be able to ditch the mason and guys like Pasquale Primmadonna.

With a prefab wall you can ditch contractors all together and save yourself dough and do it yourself.

Reason #6 to use a prefabricated glass block shower wall– Don’t worry about rust between the blocks – EVER

You can imagine how a homeowner who called me to see a glass block shower wall with rust in the middle installed by some mason – back in the day. The reason there was rust is with a traditional masonry installation there are metal wires running through the blocks to make the wall stable and tie it into the supporting wall. The problem is if water gets in between the joints you’re going to have a bad situation. If the wires rusts, you’re in big trouble because the only way to fix this problem is remove the entire wall and start again. That’s a bad day (or week, or month).

With the prefabricated wall panel process the units are assembled with a sturdy vinyl track between the blocks which never rusts. Not only is that good, but the walls are sturdier than a mortared glass block wall with the wire. You get a sturdier wall. It won’t rust.

Reason #7 to use a prefabricated glass block shower wall– You can get a base designed to fit the wall

This seventh reason could be the most important one. If you’re doing a curved glass block wall or an angled one, making sure the shower pan is designed to fit the glass blocks is essential. If the base isn’t shaped exactly like the glass block wall, you’ll have a BIG problem. The reason is, you can’t cut the blocks.

With a prefab system the shower pan (which can be made of solid surface in 51 colors or a waterproof ready for tile base) can be manufactured specifically with the glass block wall dimensions in mind. What’s also nice is you can locate your drain wherever you want it. This is important especially if you have a concrete floor or it will be difficult (and expensive) to move the drain if you have a finished ceiling below.

Make your life simple. Get a glass block shower kit where the base fits the walls like a glove.

Conclusion

Sometimes it’s fun to be ‘old school.’ I still love my ‘old-school’ funk music (anyone out there remember Johnnie Guitar Watson or The Brothers Johnson?). I might even go ‘old-school’ and put a disco ball in my master bedroom, but my wife Rose might just think that’s a bit out there.

However, being ‘old school’ with a glass block shower installation can be a literal and figurative mess. It’s harder to do. It’s difficult to find a human being willing to do the job. It will take more time, cost you more and the quality won’t be as good.

If your contractor is recommending the ‘old school’ approach with a mason to install your glass block shower wall unit by unit – stop him or her before they get too far.

Research glass block shower systems and installation approaches. Get a kit which is designed with a base and wall which works together. You won’t be sorry (or if you are call me at the number below and let me have it!).

How can I (or my team) help you with this project?

For assistance designing and installing a glass block shower with a prefabricated kit anywhere in the United States call us at Innovate Building Solutions at 877-668-5888. For a local installation service and supply contact Columbus Glass Block at 614-252-5888 or Cleveland Glass Block at 216-531-6363.

If you’re a remodeler or builder and want practical advice on remodeling products, industry trends, marketing and sales tips to grow your business (and cut day to day hassles), start reading my newest blog – Innovate Builders Blog. It’s packed with ideas you can use now. Click here to Sign Up for the Innovate Builders Blog.

Mike Foti

Theresa – thanks for your question. We would recommend to mount to the vertical wall – not to drill into the curb. The problem with drilling into the curb is you can create a place where water could leak through. I would recommend you contact a tile shop who sells glass tiles and ask them how to safely drill through glass tiles. I think this will be your best bet. Mike – 877-668-5888

Theresa Graf

Hello,

I have recently had a glass tile shower installed and would like to put up a glass block wall that is 24” wide x 60” tall. I cannot find a local contractor who will drill I to the glass tile to mount anything. Is it possible to have the wall I want without anchoring it on the vertical? Anchoring it to the floor is not a problem as curb is ceramic mosaic tiles. Also, if this is doable, where can I get the pre-fab wall?

Thank you!

Mike Foti

Larry – I’d be glad to assist you with this. I’ll email you to go over pricing and see how I can help next.

Mike

Larry Serrano

Interested in a prefab straight glass brick shower wall. Approx 4 brick wide and 10 brick high (estimate)

Jeff holm

I too am planning a 36 x72 glass wall round opening side and top, suggestions?

Mike Foti

Jim – you can build a glass block wall any height – but the key is to anchor it in every 16″ to 24″ of height (every 2 to 3 blocks high). With the prefabricated system we sell we will include anchors in our system to do this every 2 blocks high. You can make the wall any width you want. If you want any more design advice (or wholesale direct supply) of prefabricated glass block shower wall panels call us at 877-668-5888 or fill out one of our on-line forms. Thanks for reading – Mike

Jim Horner

mike…how long and high can I build a glass block wall? it will be anchored to one wall. shower will be 6′ in length. so how far off the anchored wall can I go with the wall height?

Mike Foti

Ray – this is quite an industrious project you’re looking to do! For the the first on if it’s possible to have a completely ‘free-standing’ glass block wall without supporting it into a wall on the side the answer is yes – this is possible. We did a commercial exterior wall like this and there were ‘supports’ in between the blocks to provide structural stability. These supports were anchored into the ground – but you didn’t see them with the finished wall.

Now on to the question about a ‘T’ block – the answer on that one unfortunately is no. No manufacturer has attempted to make a block like this (I’m not sure how they’d pull it off in the glass block manufacturing process) – or even if you did, if you would have enough sales to justify the expense of the mold.

A wall like this will likely have to be built at the job site – since the prefabrication process requires using standard shapes and sizes. Feel free to call our office if you want more input and/or to send us the drawing of your concept. Our company likes to help people “Innovate” (yes – that’s a bad pun intended), but it’s true – it’s fun to push the boundaries in design. Call 877-668-5888 and ask for me if I can help further. Mike

Ray

Hi, I would like build a G shaped bathroom with shower from 405 8″x8″ glass blocks: 7’Hx11’L back wall against concrete block units with waterproof membrane between connected at 90 degrees to a side wall 7’Hx 7’L which in turn is connected to a small 7’Hx4’L privacy wall for the toilet.

At the other end there will be two 7’Hx3’L walls perpendicular to back wall creating the two shower sidewalls. A sliding glass door mounted to the ceiling will finish it.

Questions, can such a structure be self supporting without any bolts into the concrete block foundation? Do they sell T shape blocks for intersections like in plumbing?

Mike Foti

Thanks Larry – we can certainly quote a prefabricated system for you. I’ll plan to send you an email with some pricing and links. Mike

Larry Phelps

The block wall I am installing is pretty basic. It is 72″ H x 36 W with one vertical side rounded. I am pretty handy with block and brick but have never tackled glass block Your solution seems to be the answer. Can you quote me the approximate price? I am located in Green Valley, AZ.