A Step by Step Guide to Select a Glass Floor or Bridge

Updated February 2, 2019

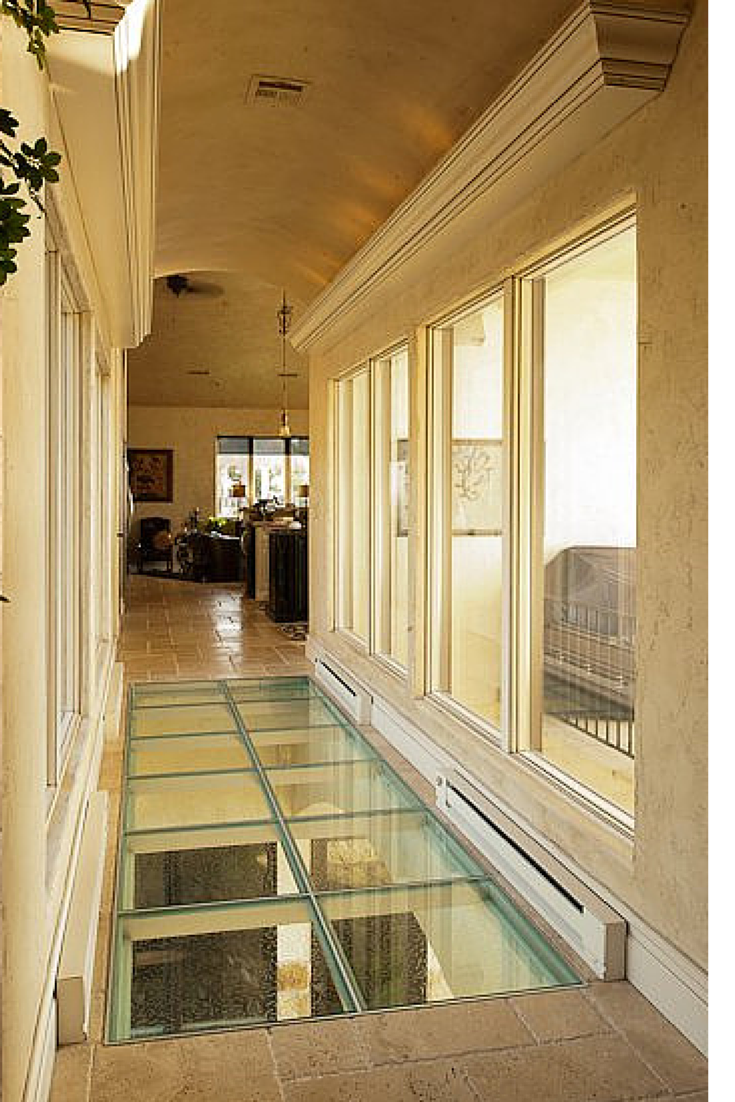

There is a mystique around a glass floor – whether you are walking on one at the Eifel Tower or in a luxury home. After someone gets done oohing and aahing they will often ask themselves, “Is this floor safe? Can it be private? Will it be slippery? Does it scratch easily?”

These are just some of the questions I’ve been asked when designing a glass floor or bridge for an upscale home or a commercial business. This got me to thinking it would be helpful to create a simple step by step guide to help people through the process of selecting the right glass floor for their specific project. The 8 1/2 steps below can serve as a primer through the glass bridge or glass floor selection process.

- Step 1 – Determine if you need clear or obscure glass – A key decision is obviously the type of glass (as will be explained in step 2) – but before you can choose a type of glass you’ll need to think through if you want the floor to provide a transparent view or to obscure the view (yet still allow light to flow between floor levels). A common misconception about glass floors is that they are all see-through. While many want the floor to be clear to show off an art collection, wine cellar, water feature, sports memoriabilia or an interesting room above or below – this is not always the desired goal with a glass floor. For many projects the objective is to move passive light into a lower level without sacrificing the privacy of the people walking on the level above. This goal is achieved when glass floors have a sandblasted top finish or an acid etched bottom surface.

- Step 2 – Choose your glass – All thick pieces of glass are not made to be used as glass flooring. Here are 3 proven choices for a structurally safe glass floor:

- Laminated and tempered flat glass floor panels – These floor panels are 1” to 1 ½” thick with a tempered glass top surface and lamination layers in between for added strenghth.

- Glass pavers – 1” thick solid pavers can be circular or square and are set within an aluminum, stainless steel or cast iron framework.

- Cast glass – Usually 1 ½” thick, cast glass is made in a mold as solid one piece panel.

- Step 3 – Do you want an engineered system – You wouldn’t want to buy a new car without knowing it had sound engineering and safety ratings. To choose a glass floor you – and others – will walk on you’ll want to have the same assurances of safety. It is for this reason I highly recommend to my customers they choose a glass and framework system which has gone through architectural testing to prove it is designed and tested for your specific use – whether it’s for a custom home or a commercial building.

- Step 4 – Consider an anti-skid top surface – In some cases a smooth top surface for a glass floor may be adequate (ex. Low traffic areas or where you want to have no obstruction for a view below) – but in most situations I recommend using an anti-skid top textured surface. This surface is enhanced with a ceramic glass frit or the top surface is sandblasted. The anti-skid surface will not only make the glass safer to walk on, but it will help to minimize scratches.

- Step 5 – Ask, “Is waterproofing required?” – If you need an exterior glass decking system or a glass floor in between two interior floor levels you will generally not require a waterproof system. On the other hand if you’re using glass flooring on a rooftop with a finished room underneath it will be essential to select a fully engineered and waterproof system. While waterproof systems are approximately 2.5 times more expensive than water resistant systems they provide the dual function of a walk-able surface above with light transmission below.

- Step 6 – Determine the size, design and shape of the glass lites – Glass floor panels can be made in virtually any shape (squares, rectangles, circles, angles, trapezoids etc.) allowing for a high degree of design flexibility. In order to determine the design of the glass pieces it’s important to take into account weight and the potential need for structural support. For example a common 1” thick glass floor will be 11.5 lbs. per square foot – so a 3’ x 5’ glass panels will weigh approximately 170 lbs. Make sure to have the panels made to a size which can be handled by your installation crew. It’s also preferred to design the panels to minimize structural support through the middle of the floor (if possible). With the most popular 1” thick laminated glass floor panels it is possible to span 4’ without the need for structural support through the center.

- Step 7 – Coordinate the floor with your architectural design – Make sure to coordinate your glass floor with your design style. If you want the traditional feel of pavers on the streets of New York City a concrete system with circular glass pavers is best. For an industrial or retro look a metal grid with square glass pavers is cool. For a sleek contemporary space the large continuous glass panels are the preferred selection.

- Step 8 – Light it up – For 24/7 impact adding illumination can create a wow feature – even …and maybe especially – at night. Right now I’m working with a vacation rental home owner on the island of Thomas on an exterior decking application which will have an LED lighting system around the perimeter of the floor. This floor will stand out during evening parties and events.

- Step 8 ½ – Call for help – While it’s nice to know the overall steps to choose a glass deck, bridge or floor you may still want to get help specifically focused on your application. Call Innovate Building Solutions at 877-668-5888.

If you’re a remodeler or builder and want practical advice on remodeling products, industry trends, marketing and sales tips to grow your business (and cut day to day hassles), start reading my newest blog – Innovate Builders Blog. It’s packed with ideas you can use now. Click here to Sign Up for the Innovate Builders Blog.

Mike Foti

Boris – thanks for your nice comments. It sounds like you’ve got quite a think piece of glass with multiple layers. And while my ‘gut feeling’ says you’ll be fine with the 3 sided support – I’m not an engineer (although I went to college with a lot of them!).

I would recommend you get with a professional engineer to make sure the glass bridge is safe – that’s the most important thing. They should be able to run calculations to help you – Mike

Boris

Hi Mike, long time fan, first time commenter.

I have a beautiful piece of laminated walkable glass (meant to be walkable skylights, left over from some university job). It’s 5 layers, 2″ think, the top is very skid proof, and it measures 23″ by 60″. Inspired by your blog, I want to make a walkable glass bridge where the second floor overlooks my kitchen, for that WOW factor.

That five layer edge is so beautiful, that I want to leave the majority of one 60″ side exposed, to be visible from below. The other sides will have very serious joist support. My question is: can this bridge be supported with a frame on three sides only? And if so, would a wood frame be sufficient?

Reuben

Sorry. I meant to say 4′ x 12′ not inches.

Mike Foti

Reuben – our company doesn’t offer plexiglass for glass walkways – so I think you’d want to get with an engineer from a company who does supply those to see. However, we can supply structural glass flooring (which would be 1″ thick) for this application and constant humidity will not be a problems for a structural glass product. I would recommend the glass pieces would be about 4′ x 4′ in size and have a ‘spanning member’ (or pieces in between). If you want to explore the glass option call me at 877-668-5888. Thanks for reading the post – Mike

Reuben

Hi Mike. I have a project at a coastal home right on the beach and the owners want a 4″ x 12″ walkway inside the master bedroom to be glass. Can 2″ thick plexiglass be used for this? Do you sell other types of glass that are more appropriate for this kind of project where there will be constant humidity since it’s on the beach?

Mike Foti

Otto – I think we’d want to see pictures of what you’re dealing with before giving you any thoughts on this. I will likely want to share this with the engineering team – Mike

otto martinez

Hi Mike:

I landed the job of replacing broken glass floor that was installed through out the entire lobby of s residential building . The triple laminated glass is supported by a “stainless steel”point support system which was installed over a shallow water feature that covers the entire lobby. The idea seemed ok in paper but when they completed it , they had to use the non slip film which gave the glass a frosted look and then the water is not visible under the glass . All the glass is broken at the corners due to the stress caused by people walking . When we removed one glass, the point support spider dust was all terribly rusted . The client wants to clean it and keep it.

1- have you ever seen a design intent like this one ?

2- what can I use in the PSS to minimize the stress on the glass ?

Thanks for your advice

Mike Foti

J – thanks for your question. While I have knowledge about glass flooring I won’t pretend to be a structural engineer. I would seek one out for your technical question. Thanks for reaching out though – Mike

J. Scott

Hello!

I am designing a glass walkway for a short film. The walkway is 9′ x 3′ with supports on all 4 sides @ every 3′ but there is no structural support under the middle of the glass. The thickness of the glass is 1/2″ tempered. What kind of static load can this glass and structure support? What kind of dynamic load? We are shooting a shot from below the glass walkway and filling it with 300lbs of water. The water is only a couple inches deep and contained by a short wooden frame that rests on top of the metal frame in which the glass floor is set into. The glass does not bear the weight of the wooden frame, only the water. There is 1/8″ silicone tape between the glass and metal and between the glass and wood–it doesn’t come into direct contact with any hard surfaces. The director wants someone walk slowly on the walkway through the water if it’s safe to do so. It’s been very hard to find info on whether or not this is a fools errand and/or how to build it safely! Thank you! J

Mike Foti

Dibyojyoti,

Thanks for your question. If you can make this glass flooring area 7′ x 4′ (instead of 7′ x 5′) you can do this floor without any structural support through the middle of the glass floor and in that case the glass thickness would be 1″ thick (assuming it’s supported on 4 sides) and would have tempered glass on the top and bottom surfaces with a laminate layer in between. There are details for the support structure we could send you if you want to contact us. Here’s a link to a form you can use, if you’d like to do this – thanks – Mike – https://innovatebuildingsolutions.com/contact-us/free-consultation-estimates

Dibyojyoti Saha

Hi Mike,

I am planning to install a walkable glass flooring of 7 ft x 5 ft. What should be the appropriate glass type and thickness? what support structure should be suitable?

Mike Foti

Alex – in order to have ‘transparency’ you’ll likely need an ‘open space’ below the glass pavers. What are your tiles currently set in? If you’d like to call about this project contact us at 877-668-5888. Mike

Alex

Hello Mike,

I have an outdoor patio where I would like to replace ceramic tiles with glass tiles and figure out a way to create transparency. I would love to learn if this is possible,

Best,

– Alex

Mike Foti

Feel free to call us at 877-668-5888 and we’d be glad to talk to you about an anti-skid glass flooring system. Mike

Sumit

Sir I want to acquire about the anti skit glass floor

Mike Foti

Kokoro – we sell a 4 1/4″ deep aluminum framing system which provides support for our glass flooring. My guess though would be since you have an older system it’s highly unlikely what we have will work for you. I would recommend measuring from the top of the support to the support shelf (or ledger) underneath how much room you have. You’ll want to get with either a steel or aluminum fabrication company to get either a stock size or a specially designed framing system made for your glass floor. Feel free to call us at 877-668-5888 if you need more help. Mike

Kokoro

Hi mike, we are doing a remodel, and we are redoing the floor. There was an existing glass floor in the house when we bought it. We saved the glass but unfortunately didn’t save the metal framing… do you guys sell that or do you know where we can purchase it? I’m not even sure what to look for. Any info is appreciated. Thanks.

Mike Foti

Ricky – that would be fun to help you – I’ve never been to Ireland (the closest I’ve got is Italy). Basically when you’re looking at a glass floor system the simplest way to do this is to get a system which is designed for the opening (which would not only include the glass, but also a framing system around it). I’ll email you an installation detail which you could show to glass suppliers to get you started. Mike

Ricky

Hi Mike, Greetings from Ireland, I want to put a frosted glass panel (3x2ft approx) in a bathroom floor upstairs to allow light into the kitchen below. Could you please email me any information that might help me research the job I need to find a company here that might supply a system.

Obviously you are welcome to the job if you want to come to the emerald isle. :-)

Mike Foti

Quinn – thanks for your question. Glass floors go inside a framing structure. So you’ll want to build your structure out of wood or metal first. Then you’ll put the glass floor (and the supporting aluminum perimeter members) inside your framed system. Feel free to contact us at 877-668-5888 and I can send you more specific construction details. Mike

Quinn

I have a 2 stories house and my family room is 20 foot tall to the ceiling, and I would like to build a glass floor above. The opening space is 15′ x 15′. What would you recommend to purchase to do the project and how much if I can do the laboring myself. I want to be able to walk on it and see through as well.

Please advise or direct.

Thank you much!

Quinn

Mike Foti

Noeman

I’m not sure what you mean about a ‘spider glass roofing’ – but I’m going to assume you’re talking about a walkable glass skylight. We would usually recommend a 1″ thick system (this would consist of 2 tempered layers or glass with lamination in between). Given your size of 70″ x 70″ we would be looking at needing a stiffener in the center – it’s too large an expanse for our system anyway to do it in one piece. There may be ways to do it as one large thick piece but you’d probably need to consult an engineer and they would need to run calculations. I hope this helps. Mike

Noeman

Hi Mike .

I have to buikd spider glass roofing with panels dimensions 1800 mm width * 1800 mm length and glass thickness in specifications are laminated tempered 12 mm thick ( 2*6 ).

Is it correct or it should be more thicker with more layers??

Specially It will be walkable roof to clean it .

Thanks ,

Awaiting for your reply to my email.

Regards .

Mike Foti

Baher – for the 40″ x 44″ size you can use a 1″ – 2 part laminated glass system (i.e. your 2 sheets of 12mm laminated). Let me know if you need anything else. Mike

Baher

Mike, if I have panels that are 40” x 44” and supported all around, can I do 2 sheets of tempered 12mm laminated together or do I have to do 3 layers of 10mm?

Vimal

Hi Mike,

I would require an expert advice: I have a glass floor of 235 cm long by 27 cm wide and the glass thickness would be 1.9 cm.

I would like to know if I need to have a support underneath across the glass length since it will be in a walk-on area.

Thanks.

Mike Foti

Mike – the idea of a seating area and dance floor for a wedding sounds fun. Given the expense – and the fact glass floors are customized for each job (and the need for structural support for the glass over large expanses)- I doubt glass floors would be practical. What you may want to look into is heavy plexiglass sheets. My gut feeling is this also won’t be a solution (because of the strength of plexiglass), but it’s worth a try. Sorry our product wasn’t the solution for your party. I hope you have a fantastic wedding! Mike

Mike Rhoads

Hi, I have an indoor swimming pool that I would like to cover with a glass floor for a wedding. The idea is to provide space, seating area, and potentially dance area. Any advice for “renting” glass panels for such a purpose? I’m located in Northern California. Any glass panel rental companies you might be able to recommend?

Mike Foti

Malcolm it is possible to make a a glass floor which is .81″ (a little under your 2.2 CM by using one layer of 3/8″ thick tempered glass, the .060 lamination layer and then another layer of 3/8″ tempered glass). It is also possible to use 2 different thicknesses of glass in a flooring system. In this case the thicker piece of glass is put on the bottom for structural stability. What is the location of this project? Mike

Malcolm

Hi Mike, thanks for the fast responce to my last query. One more (i think), I’m looking at 4 floor panels 60cm x60cm, but i can’t go thicker than 2.2 cm. So i was thinking of laminated panels, 1 sheet of tempered glass 12mm thick and one sheet of tempered glass at 10mm thick. Questions, is there a problem using different thickness of glass, and if not should the thinner sheet be on the top side ( the walking side) or the bottom.

Mike Foti

Malcolm – excellent question. Actually both layers of glass are tempered – in the case of the 1″ thick flooring. In the case of the 1 1/4″ thickness (where there are 2 lamination layers) all 3 layers of glass are tempered. Let me know if there are any other questions I can answer for you. Mike

Malcolm

Laminated and tempered flat glass floor panels – These floor panels are 1” to 1 ½” thick with a tempered glass top surface and lamination layers in between for added strenghth.

Does the statement above mean only the top layer of glass is tempered?

Mike Foti

Nehemiah – while glass floors have been used on yachts and houseboats I wouldn’t recommend it for a mobile home due to the amount of vibration (and potholes) on our streets. Thanks for your question. Mike

Nehemiah Heidelberg

can i put a glass floor in a mobile home ? please email Nehemiahfh@gmail.com

Mike Foti

Harvey- thanks for your question. I will give you a call to go over this. You do not have to use a specialty contractor because we’ve got an aluminum framing system which makes this project simpler to do. We will need the size of each of the opening – and will need to get information to your contractor on how to prepare the openings to receive the structural glass panels. I will call you to see how we can help next. Mike

harvey romanoff

I am a homeowner who is planning to put a floor in an existing cathedral ceiling living room. The space (which is not perfectly rectangular) measures approx 8ft x 30ft. The upstairs level of this room have 10 – 22inch x 5ft high panes of glass that allow light into the space below. We want to allow some of this light to pass through to the room below after we install the second floor. The upstairs room will see have a ceiling height (diagonally decreases about 1 ft over the 8 ft span) of approx 13ft at its highest point and 12 ft at its lowest point. We live in central Vt (approx 25 minutes from the capital Montpelier and 40 minutes from the largest city of Burlington) Looking for an idea of costs for three panels (can be approx 3x5ft or 3x4ft. I have an experienced contractor, who I do not believe has worked with glass floors. Their is a local glass business I worked with (who installed the original window panels and has done some glass shower installs for us – he has recently sold his business). Is the install something my contractor can provide or do I need a “specialist” to do the installation? Looking to get an idea of costs for the panels and installation by a professional. 8024965166

Any information you can provide will be appreciated

Sincerely

Harvey Romanoff

Mike Foti

Louis – we recommend flooring systems which are tempered and laminated. If you have support for the system on 4 sides 1″ thickness works out well. If you only have support on 2 sides we recommend a “3 ply” (with 2 lamination layers) system which is 1 1/4″ thick. Let me know if I can answer any other questions for you. Mike

Louis Oak

What type of glass is safe to walk on: laminated, tempered, tempered-laminated? And what thickness; is 27 mm sufficient?

Mike Foti

Rob – glass flooring can be used in any temperature. This glass is tempered and laminated and won’t break under snow or cold temperatures. Are you planning on having a finished space below the exterior deck or will the space below be unfinished? Mike

Rob Pucci

How does the glass flooring hold up to the elements. I’m considering a exterior deck and we get temperatures below zero.

Mike Foti

Curtis – thanks for your email. Yes – our glass floor are used outside with a ceramic frit top surface to make them safe to walk on. One of the key things we’ll want to talk about is if you need the space below to be waterproofed. The waterproof glass floors are significantly more expensive than the water resistant glass flooring systems. It would be best to talk about this next. You can feel free to call our office at 877-668-5888.

Curtis Billey

Hi Mike

We are considering replacing our wooden deck with a glass floor and building a Greenhouse under it. We have a good steel I-Beam structure to put the glass floor on, it would be a deck above and teh roof for teh Greenhouse. Firstly, are your floors used outside (Coastal northern BC) and secondly, do you have any examples of this sort of use.

I also need to get an idea of cost?

Curtis